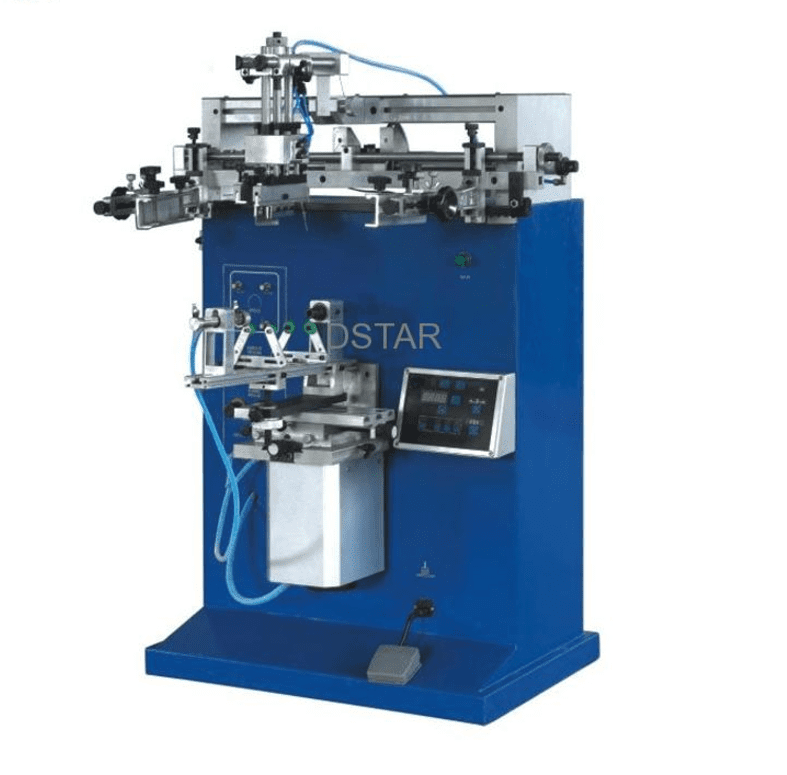

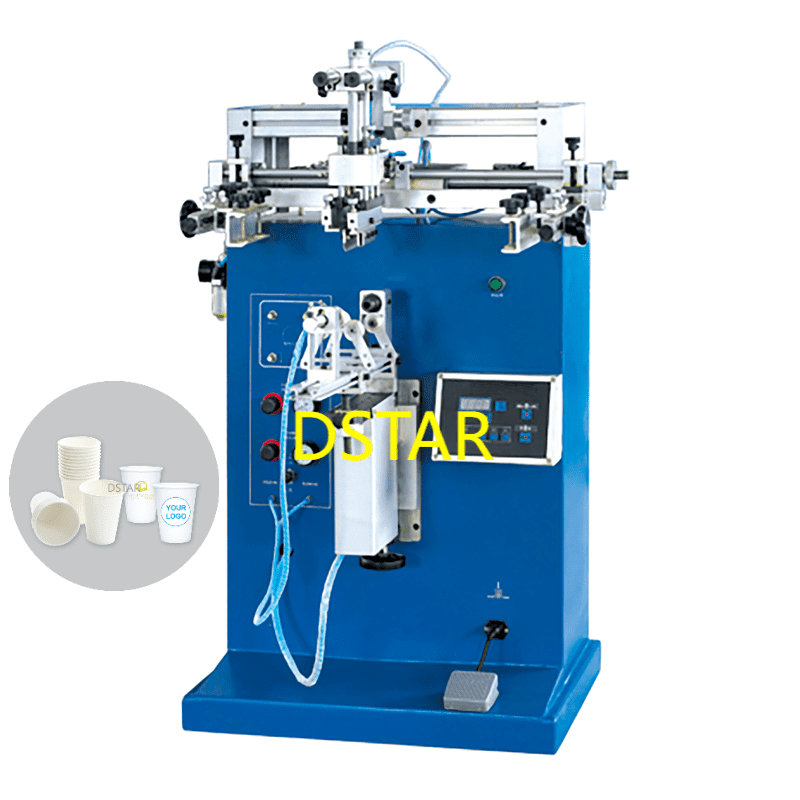

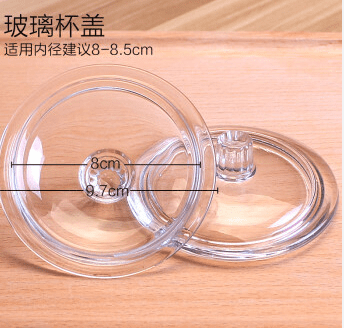

Glass Cup Lip Pad Printing Machine

Model:DX-S1

Printing color:1 color

Printing plate size:100*150mm

Ink scrapping:open ink well

MOQ:1 Unit

H.S code:84431980.00

N.W:125 kgs

Machine size:L72*W50*H135cm

Air supply:5-7 bar

Voltage:AC110V or 220V

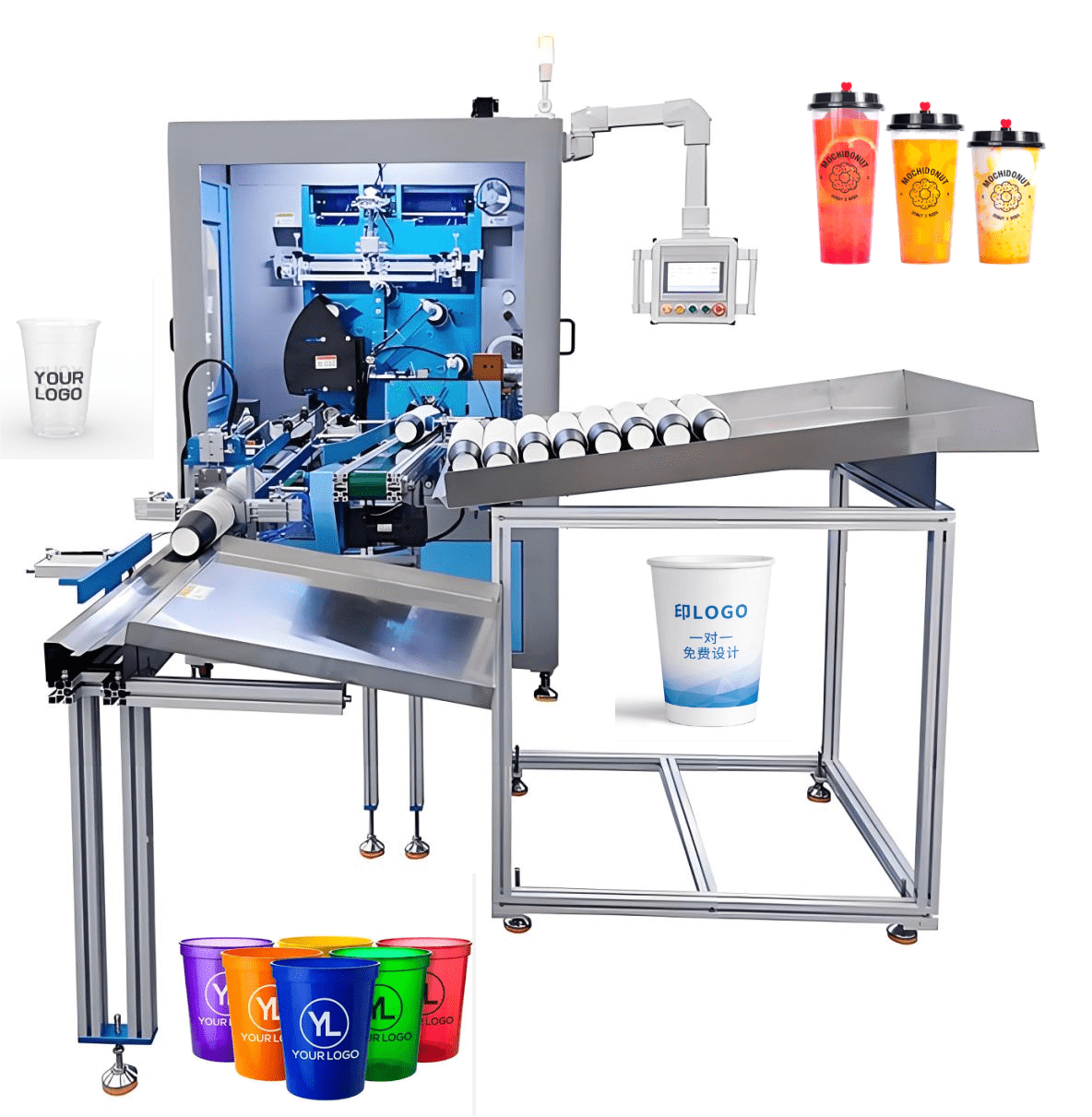

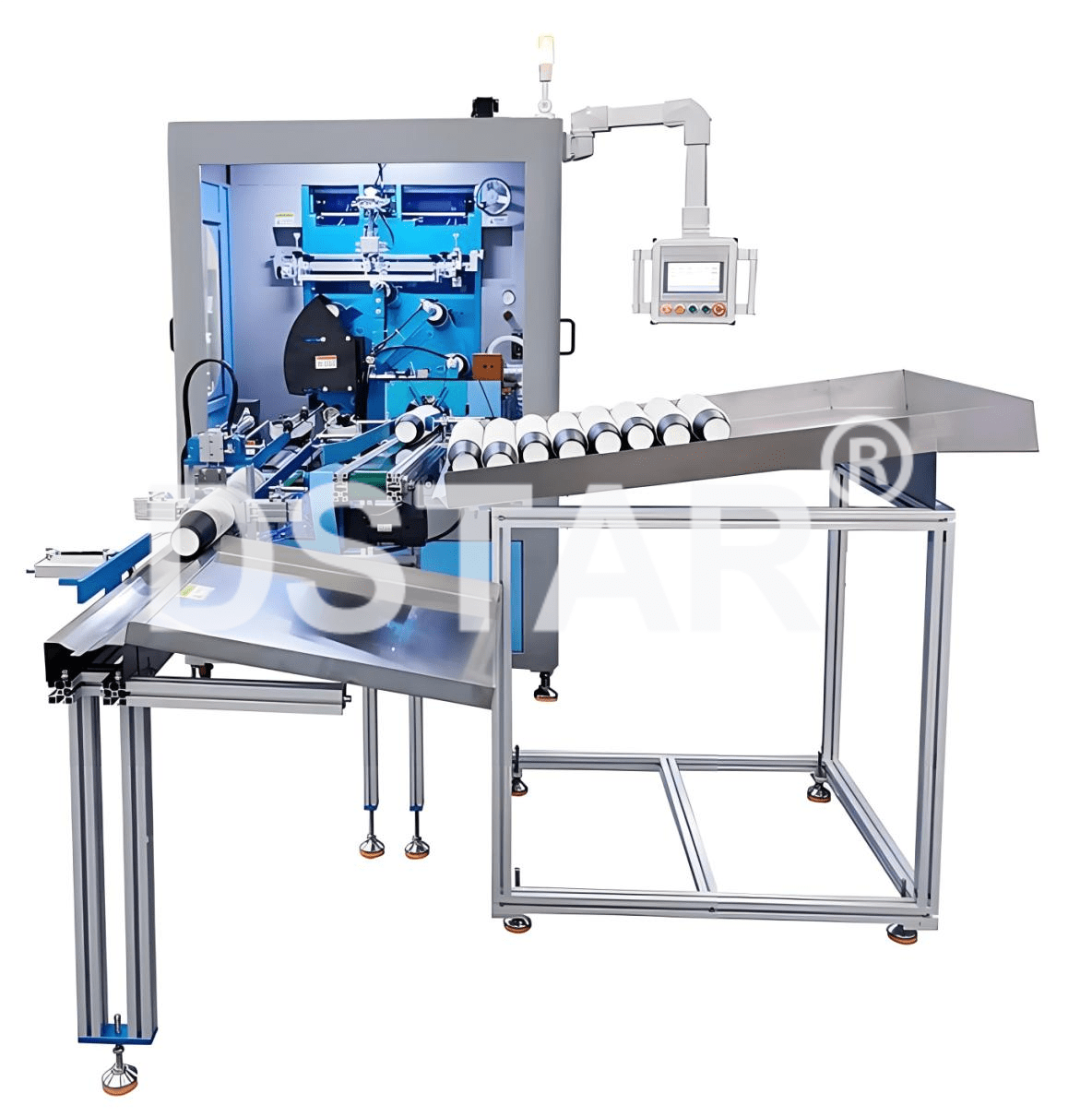

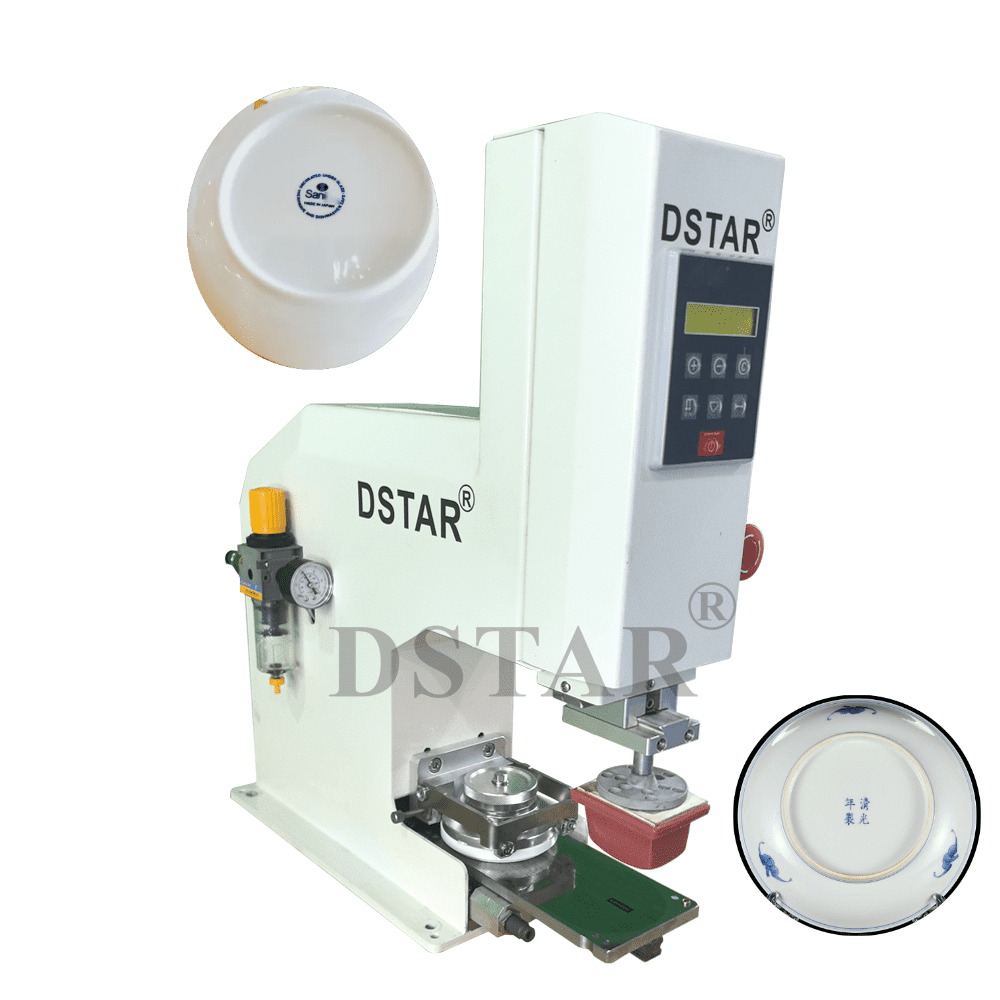

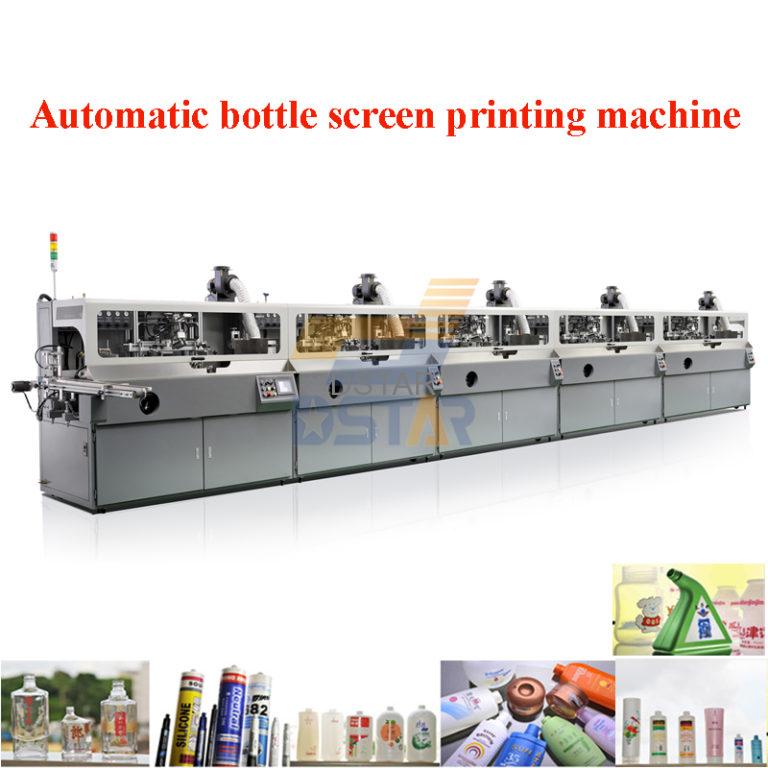

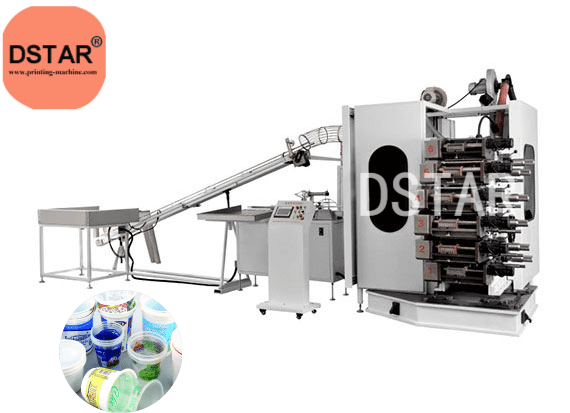

Sample Pictures

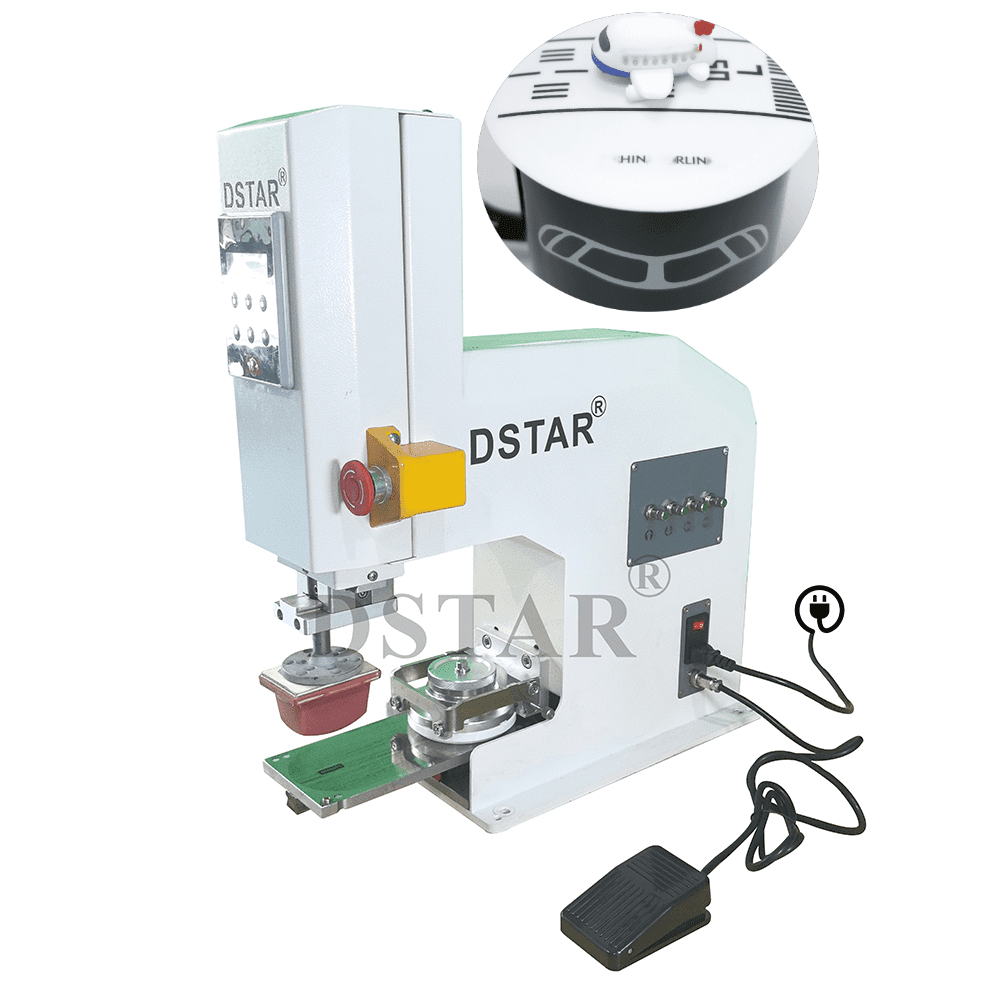

Printing Supplies

- Tampo printing plate

- Silicone pad

- Tampo printing ink and ink solvent

- Work piece fixture

- Ink blade(for open ink well system)

- Sealed ink cup (for ink cup system)

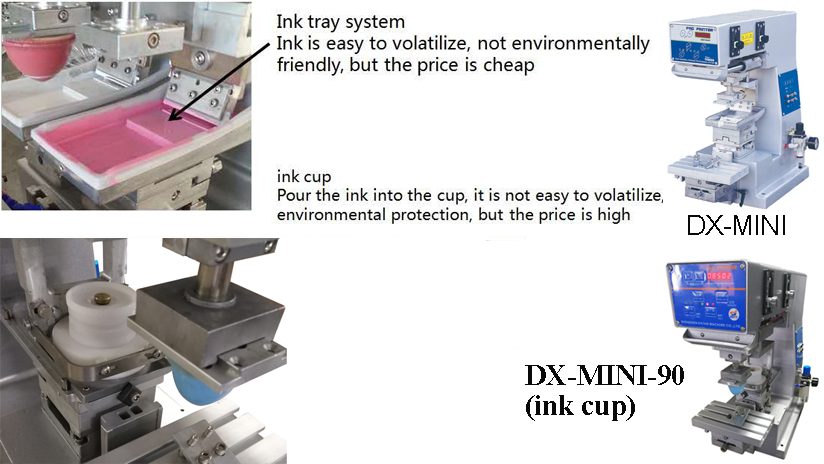

Difference between open ink well and sealed ink cup

Open ink well systems

Open ink well systems, the older method of pad printing, used an ink trough for the ink supply, which was located behind the printing plate. A flood bar pushed a pool of ink over the plate, and a doctor blade removes the ink from the plate surface, leaving ink on the etched artwork area ready for the pad to pick up.

Sealed ink cup systems

Sealed ink cup systems employ a sealed container which acts as the ink supply, flood bar and doctor blade all at the same time. A ceramic ring or tungsten ring with a highly polished working edge provides the seal against the printing plate.