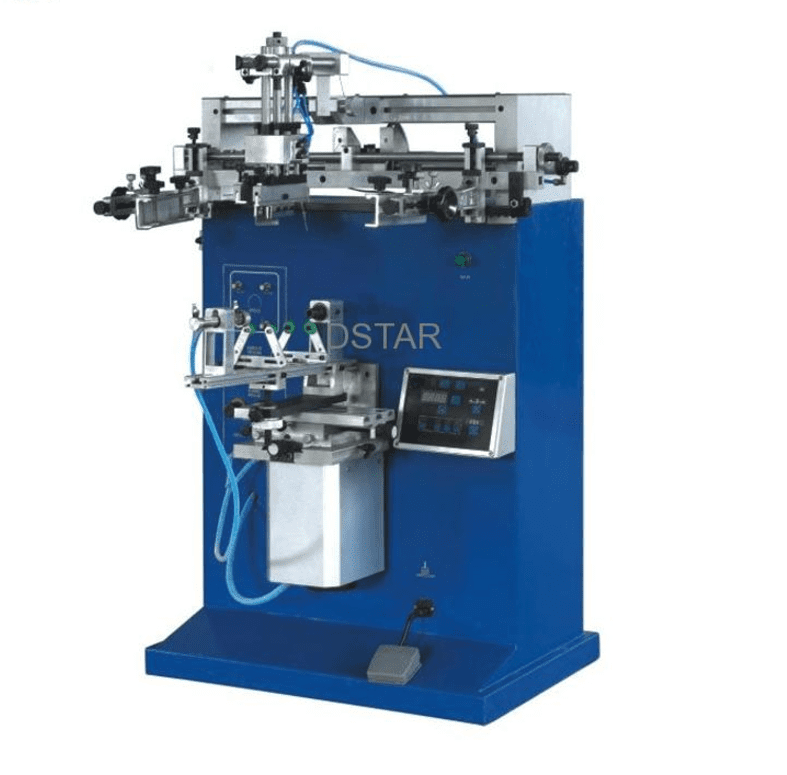

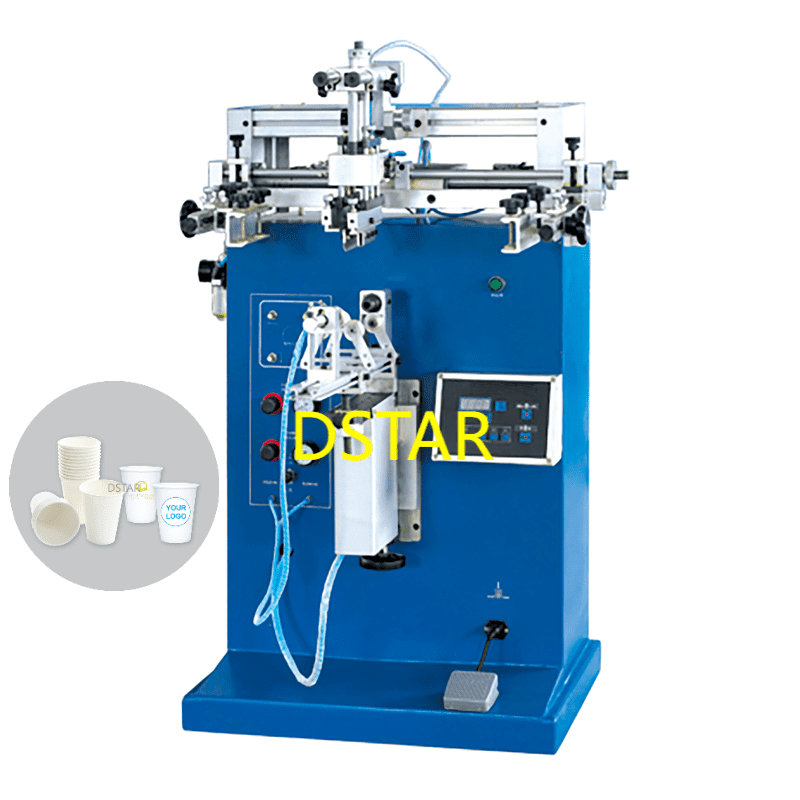

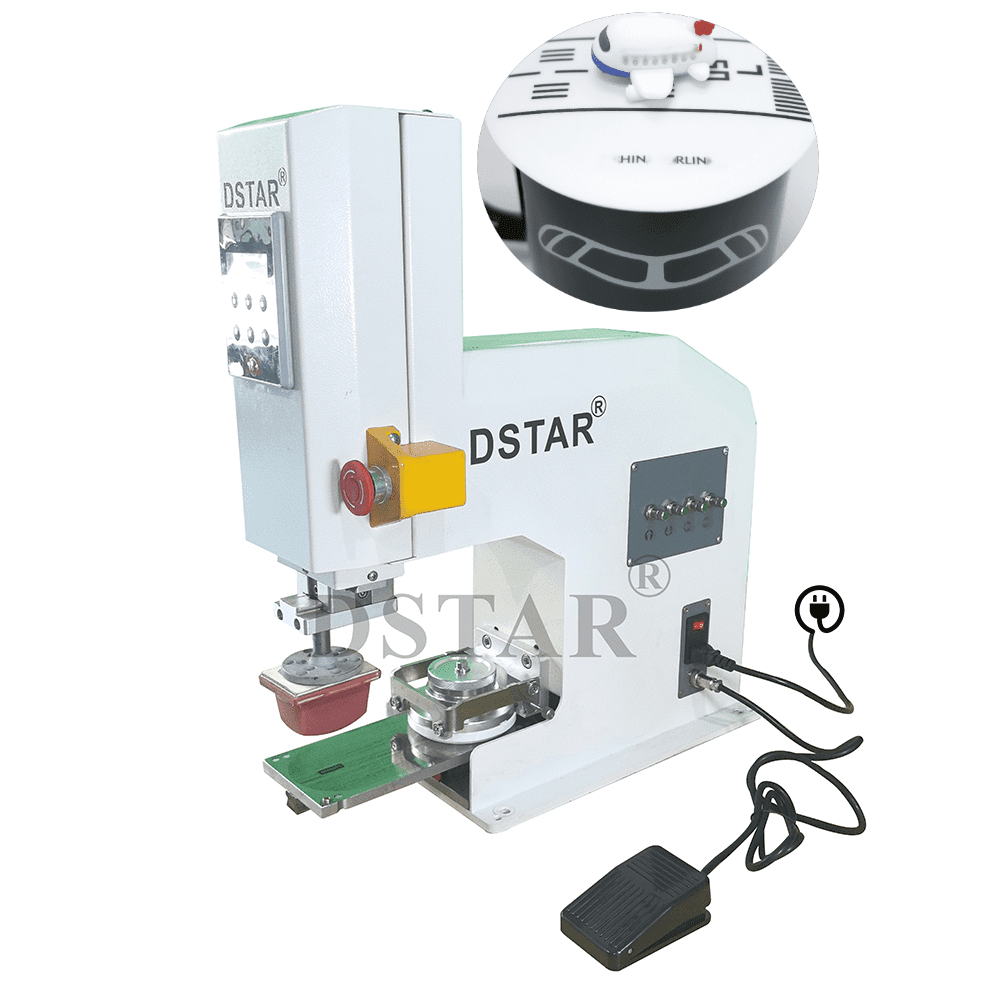

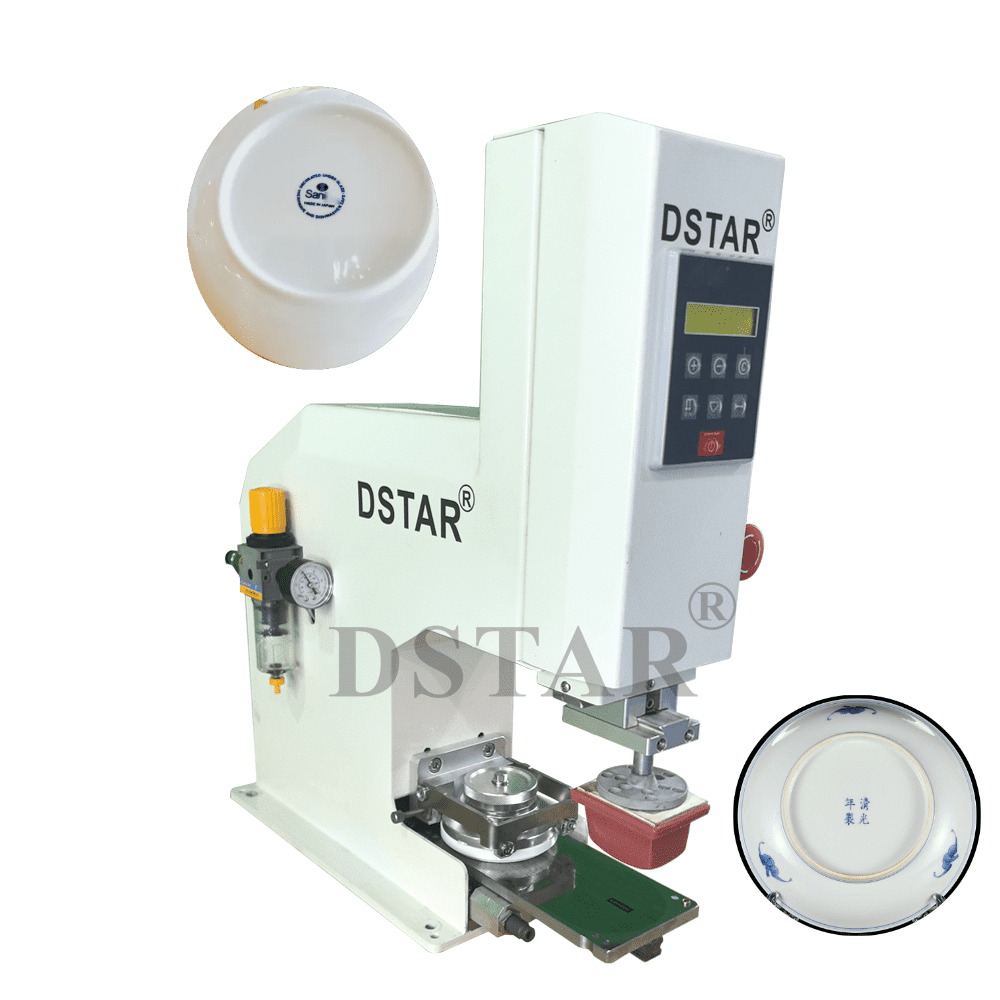

Pad Printing Machine

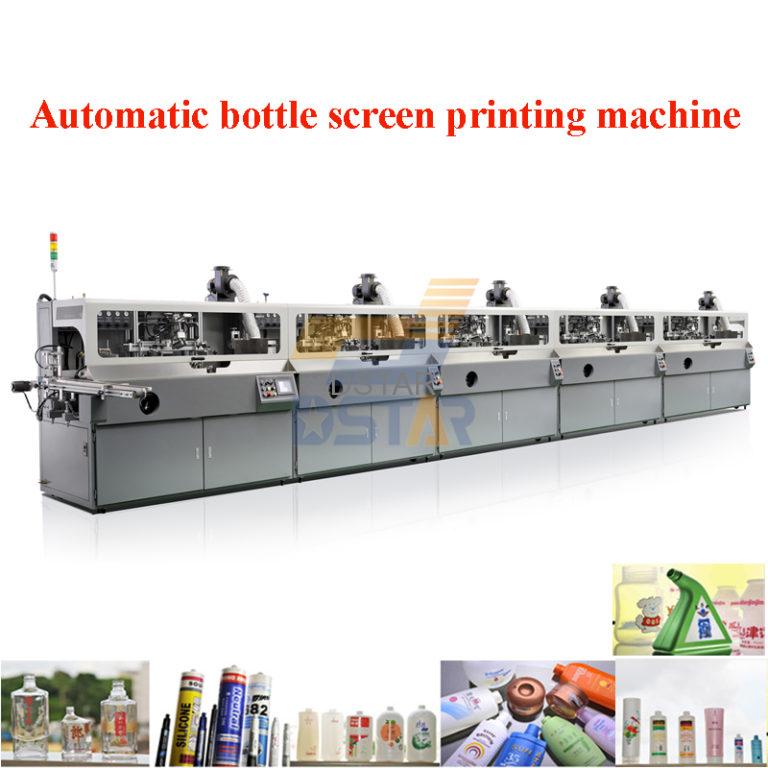

Pad printer,also as is a printing device used to transfer patterns or text from a special printing carrier to another substrate. This printing technology is often called pad printing. Pad printing machines use a special printing carrier (such as pad printing film or pad printing paper) to transfer the pattern from the printing carrier to the surface of the target substrate through heat pressing or other pressure methods.

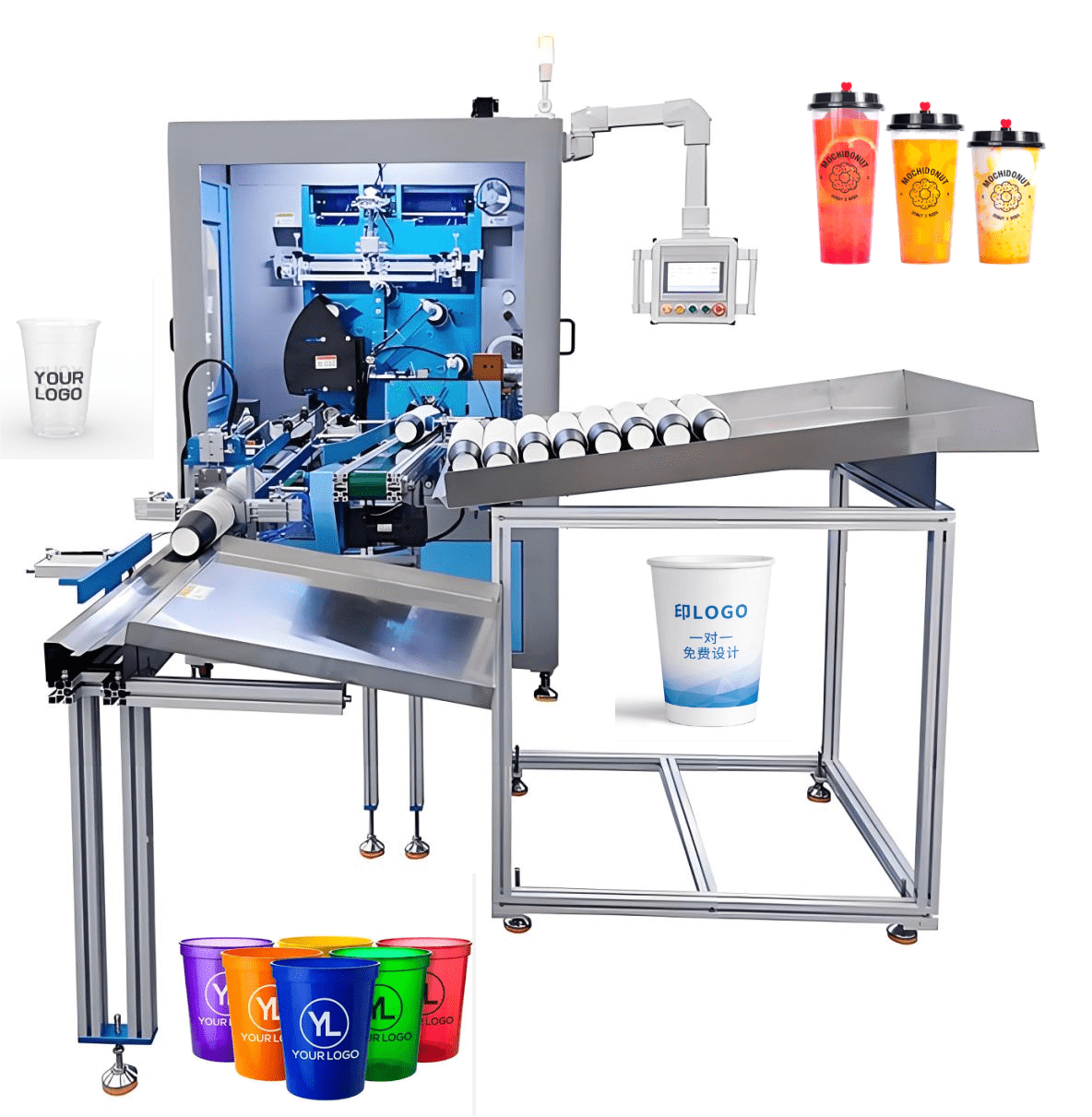

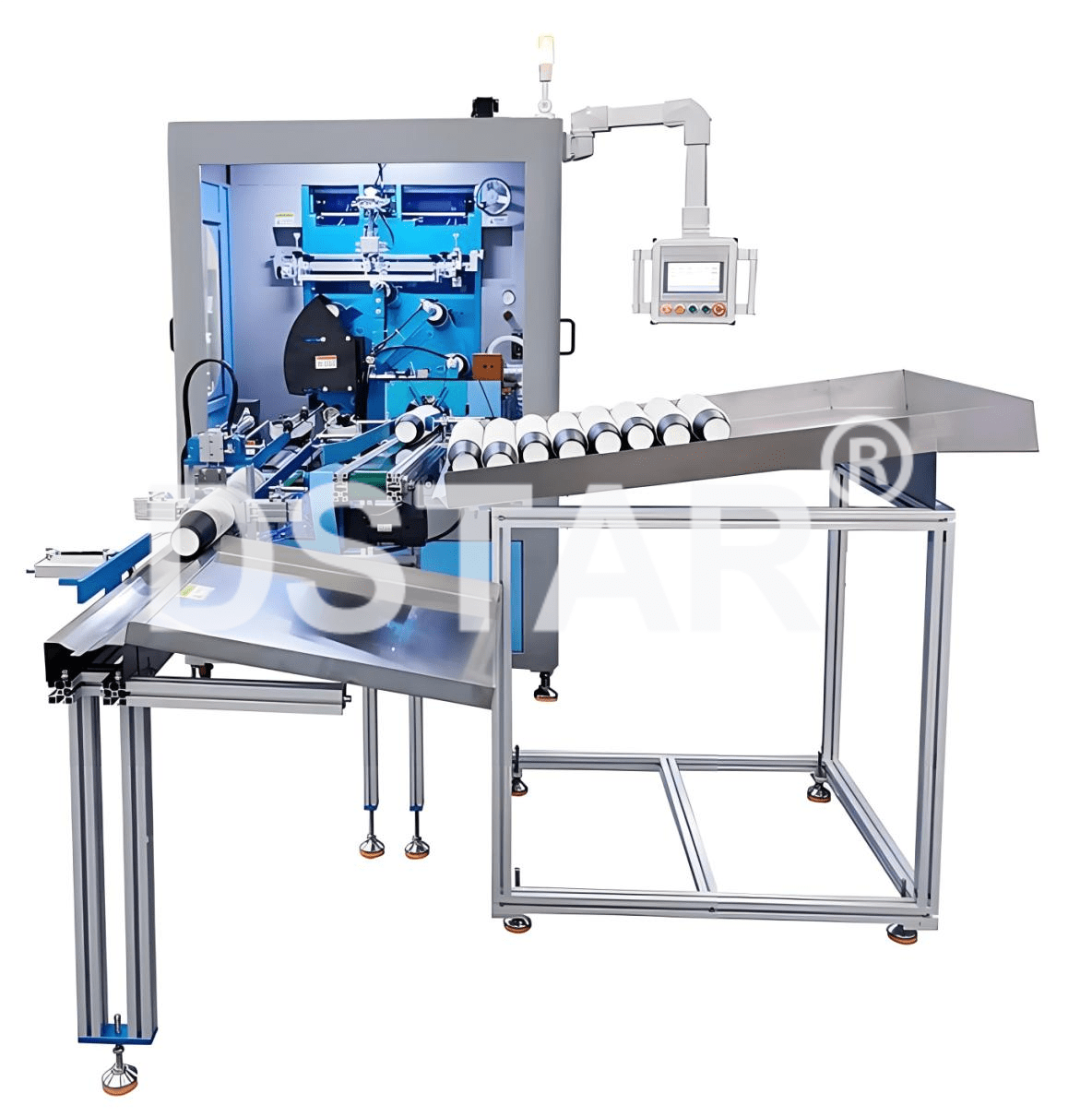

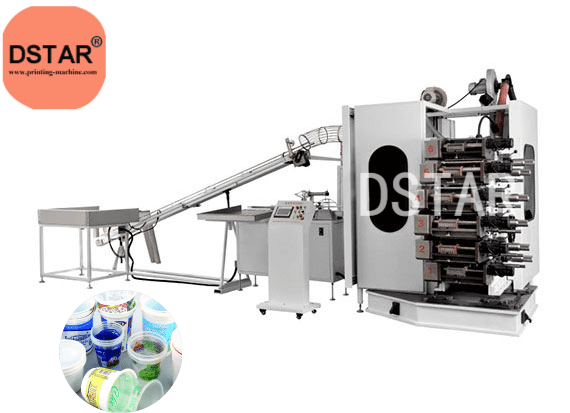

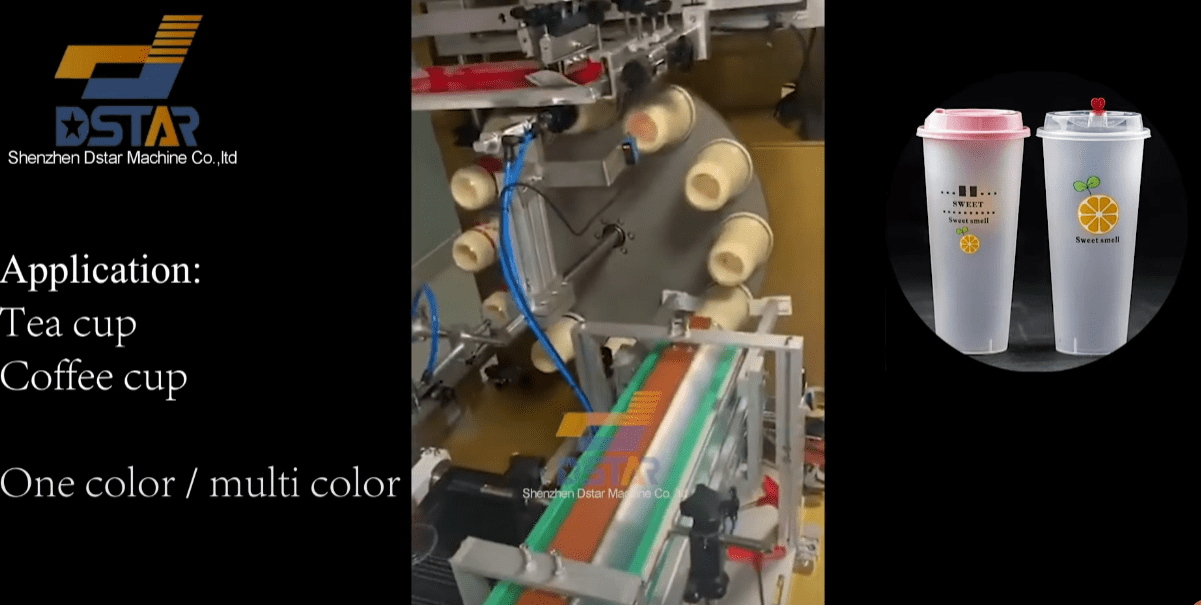

Pad printing machines are usually used to print products with complex or non-flat surfaces, such as ceramics, glass, metal, plastic, wood, etc. It can achieve high-precision, high-quality printing effects and is suitable for substrates of various shapes and materials. Pad printing technology can realize printing of multiple colors and complex patterns, so it is very useful under some specific printing needs.

The following are the steps of the general pad printer printing process:

Preparation work: Before pad printing, you first need to prepare the materials and equipment required for printing, including pad printing machines, printing carriers, substrates, etc.

Make printing patterns: Make or import the patterns or text that need to be printed on the pad printing machine, and make appropriate typesetting and adjustments to them.

Prepare the substrate: Prepare the substrate to be printed and make sure its surface is clean and flat to ensure the quality of the printing effect.

Coated printing carrier: Cover the printing carrier (usually special pad printing paper or film) on the printing pattern, and ensure that the pattern completely covers the carrier surface.

Printing process: The pad printing machine aligns the printing carrier with the substrate through a series of mechanical movements and applies appropriate pressure and temperature. Under the action of heat and pressure, the pattern is transferred from the printing carrier to the substrate surface.

Remove the printing carrier: After printing is completed, remove the printing carrier, leaving the pattern or text completely transferred to the substrate.

Drying and Curing: Depending on the type of ink or coating used for printing, the printed image may need to be dried and cured to ensure its durability and quality.

Post-processing: After printing is completed, some post-processing work may be required, such as trimming edges, cleaning the surface, etc., to make the printing effect more perfect.

The entire pad printing process usually needs to be carried out under the guidance of a professional operator, and parameters need to be adjusted and optimized according to different printing materials and substrates to ensure the quality and stability of the printing effect.

Pad Printing Supplies:

1.Pad Printing Plate

2.Pad Printing Ink

3.Sealed Ink Cup

4.Pad Printing Machine

5.Product Fixture