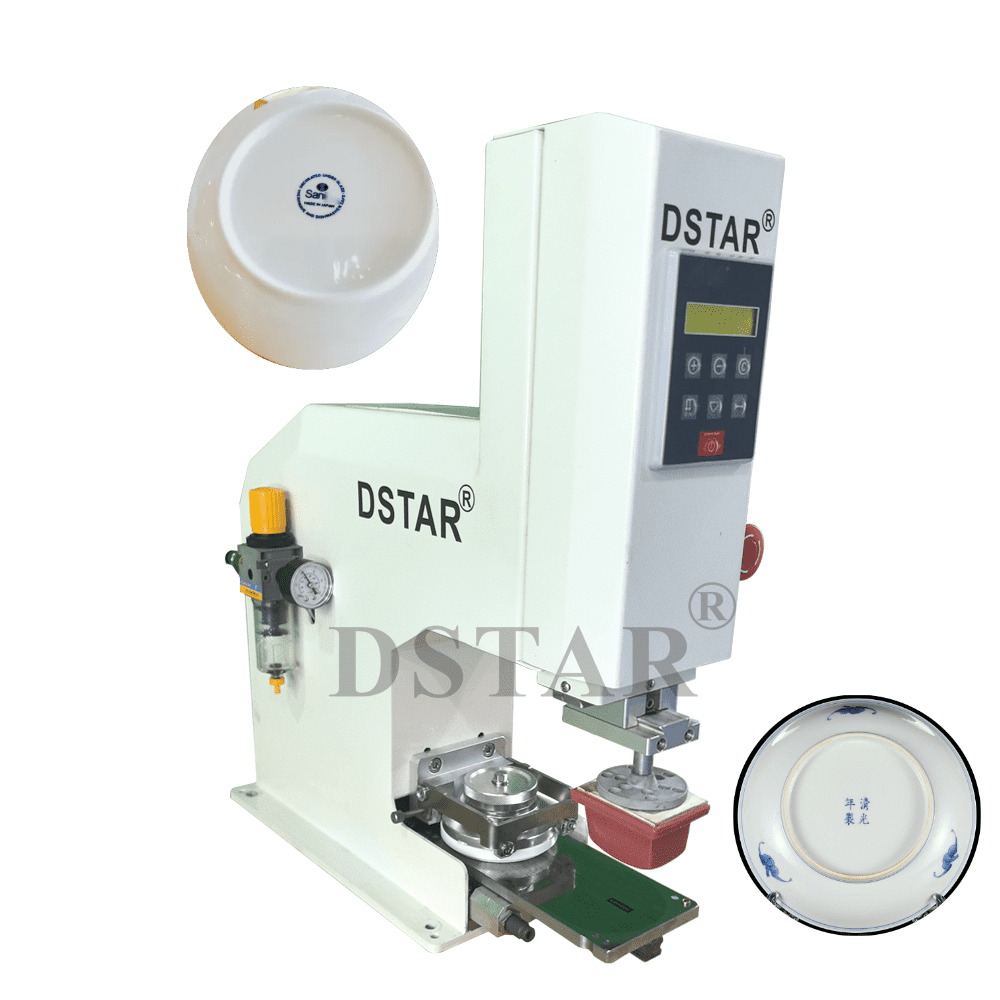

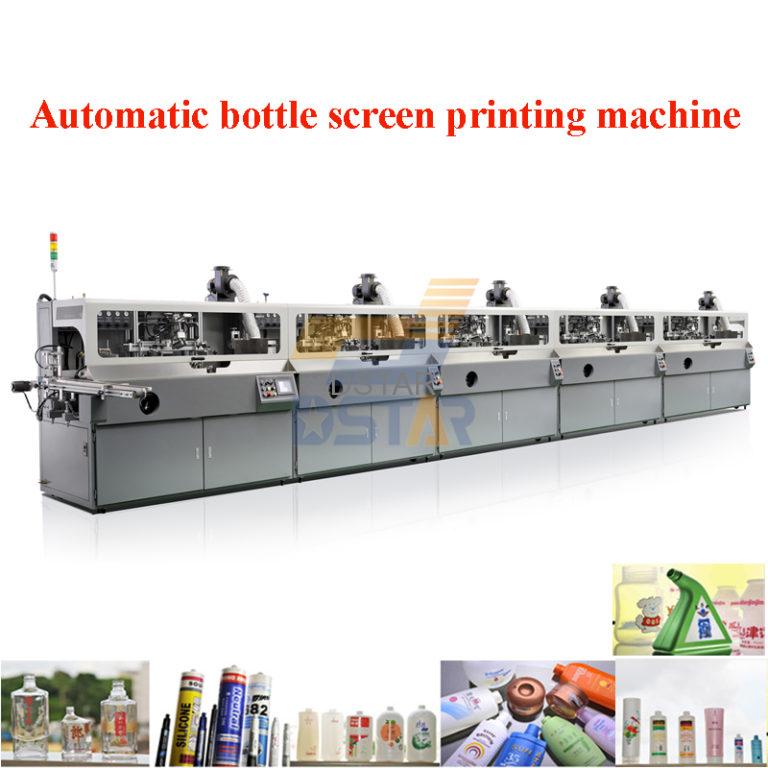

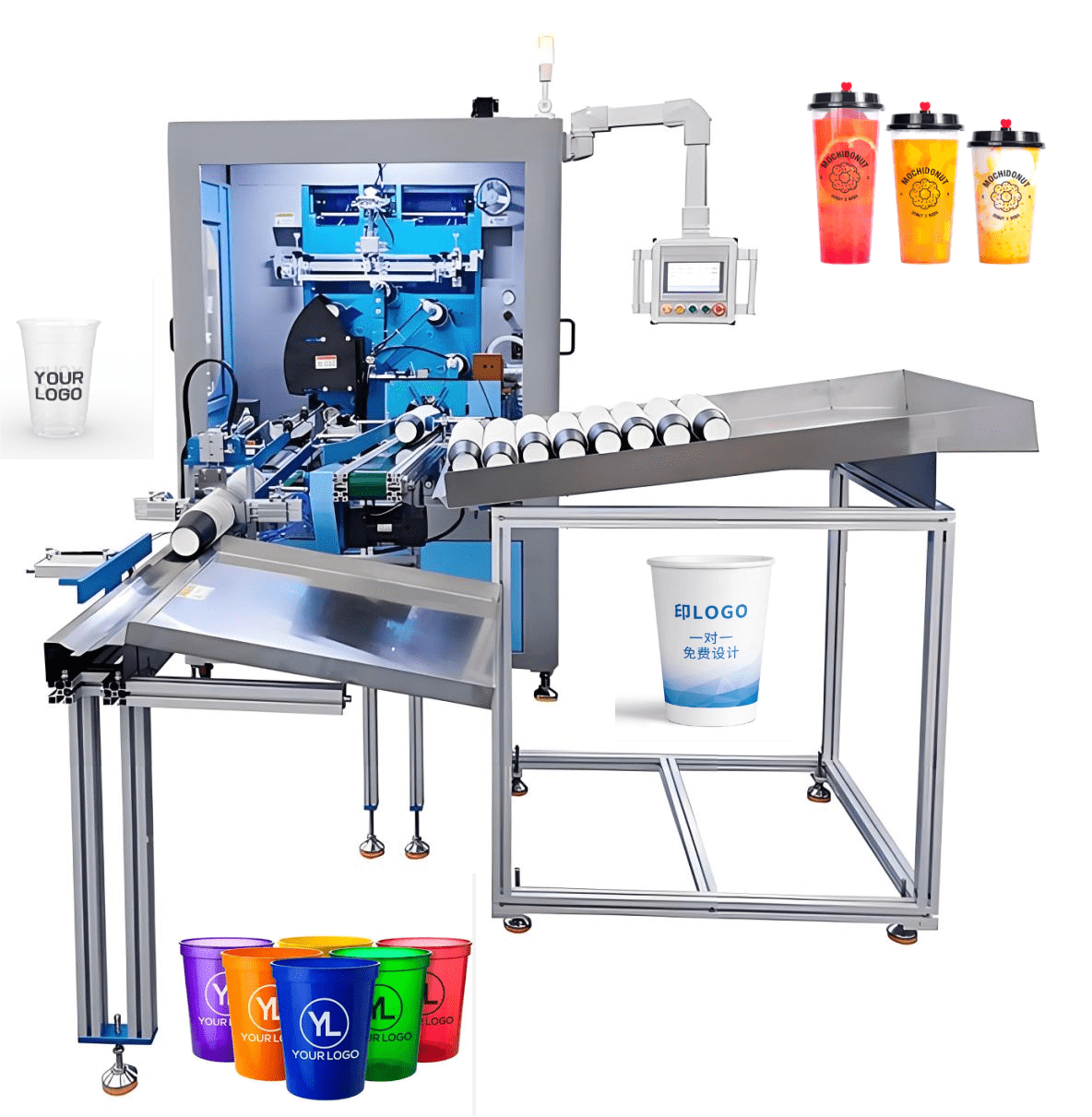

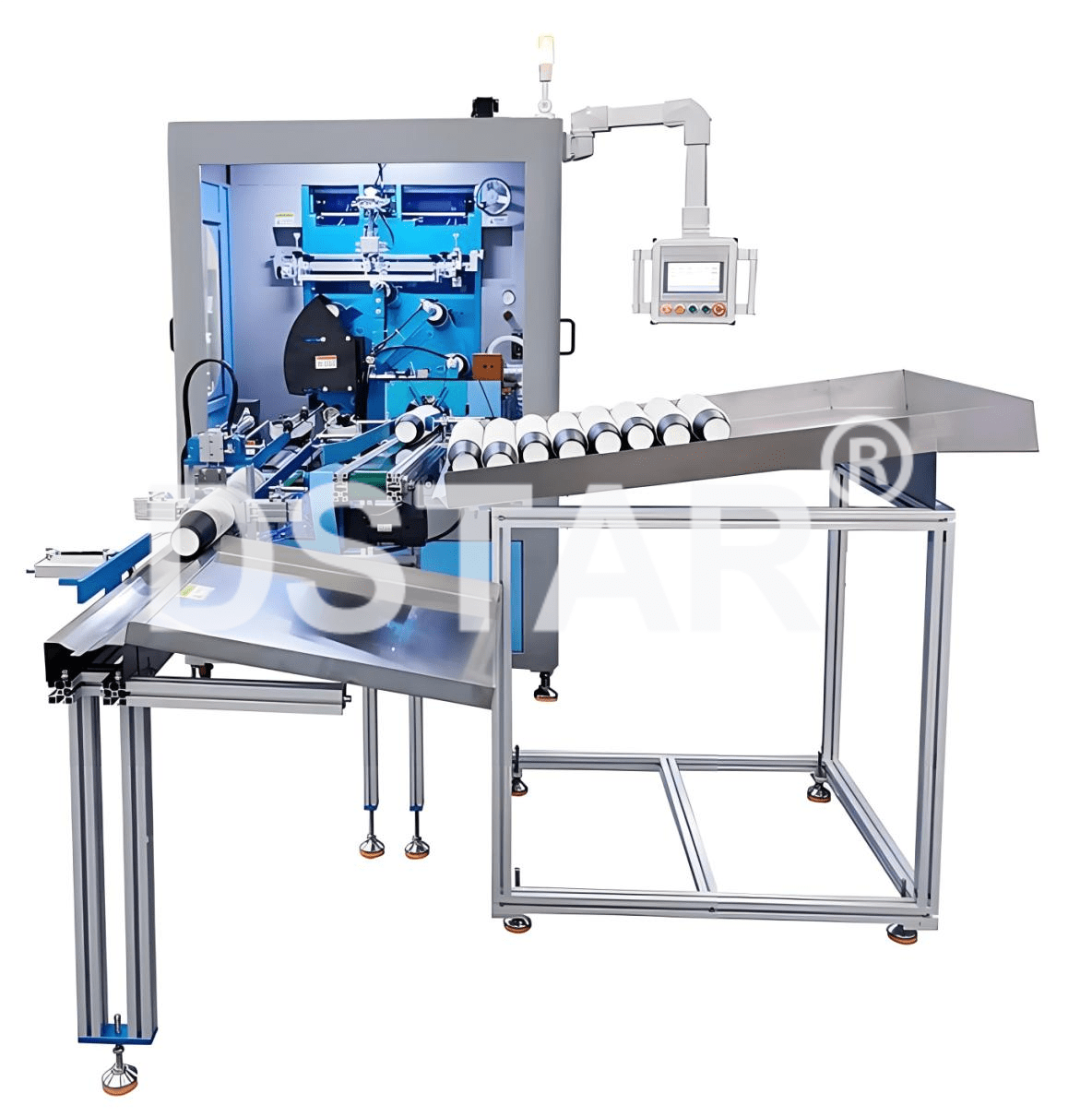

Glass Cup Logo Printing Machine for Sale

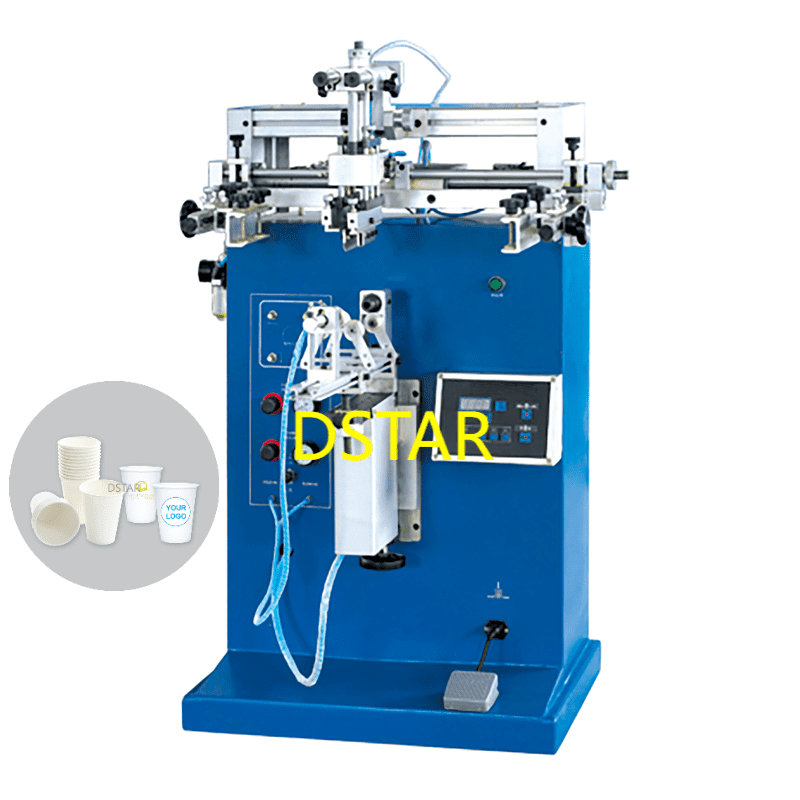

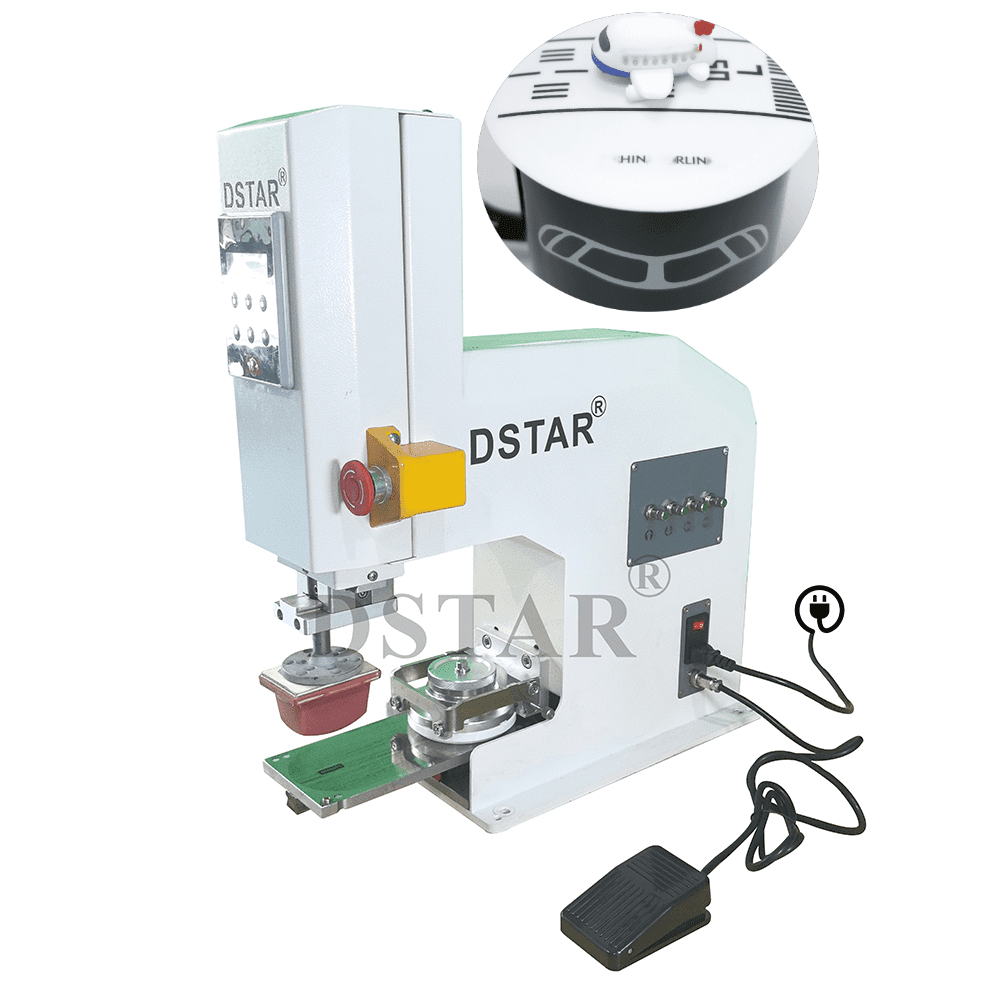

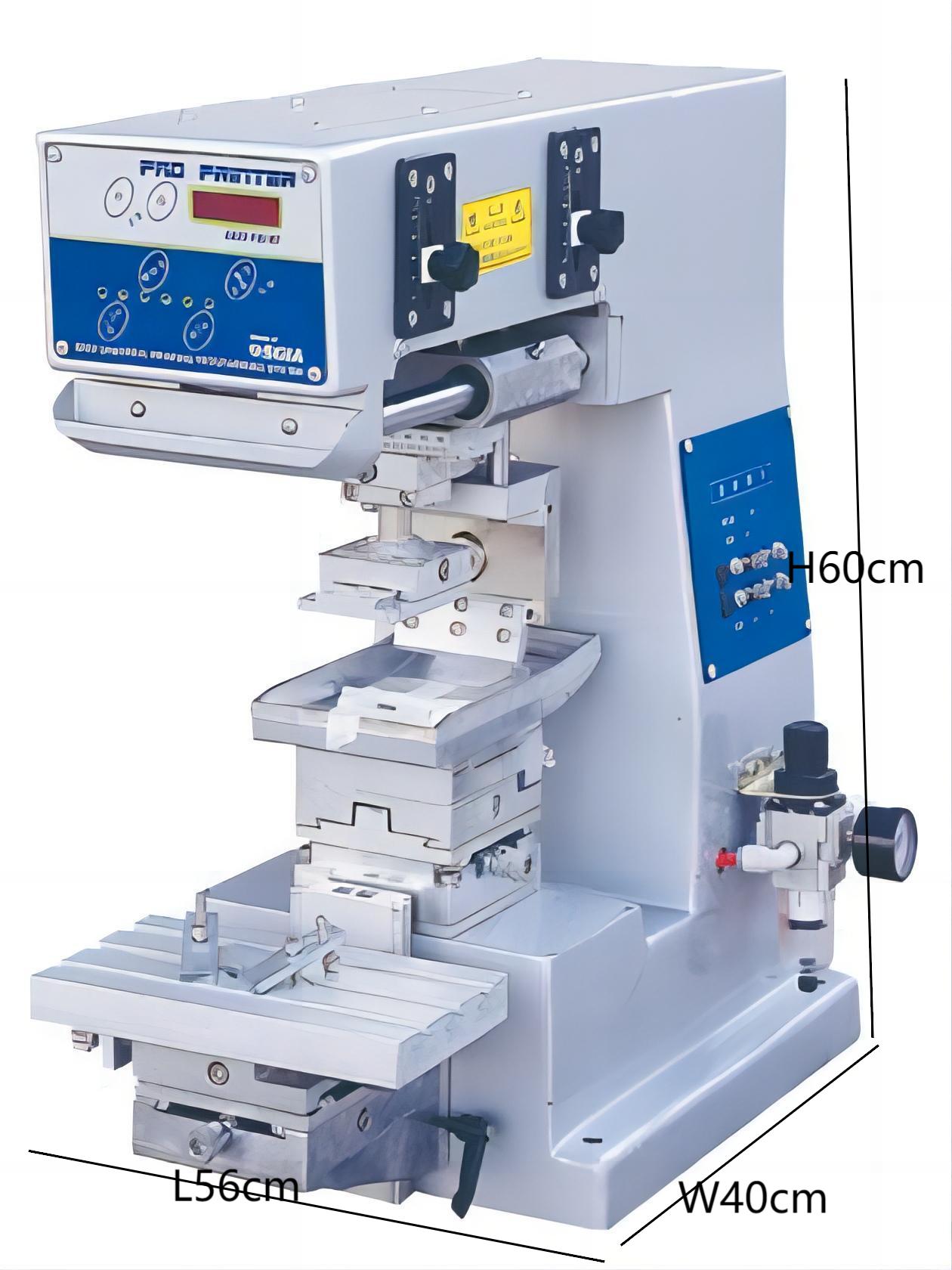

Model:DX-MINI (open inkwell system)

Standard printing plate size:10*100*100mm

Maximum printing plate size:10*150*100mm

Printing speed:1600 times/hr

Air pressure:5-7 bar

N.W:40kgs

Machine dimension:L56*W40*H60cm

Packing:wooden case

Pad printing consumables

- Pad printing plate

- Silicone pad

- Printing ink and ink solvent

- Work piece fixture

- Ink blade(for open ink well system)

- Sealed ink cup (for ink cup system)

Pad printing samples

- Stationery industry printing

- Textile printing

- Medical supplies printing

- Hardware printing

- Electronic printing

- Toys printing

- Packing printing

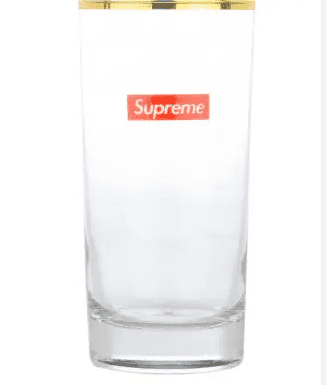

- Glass products printing

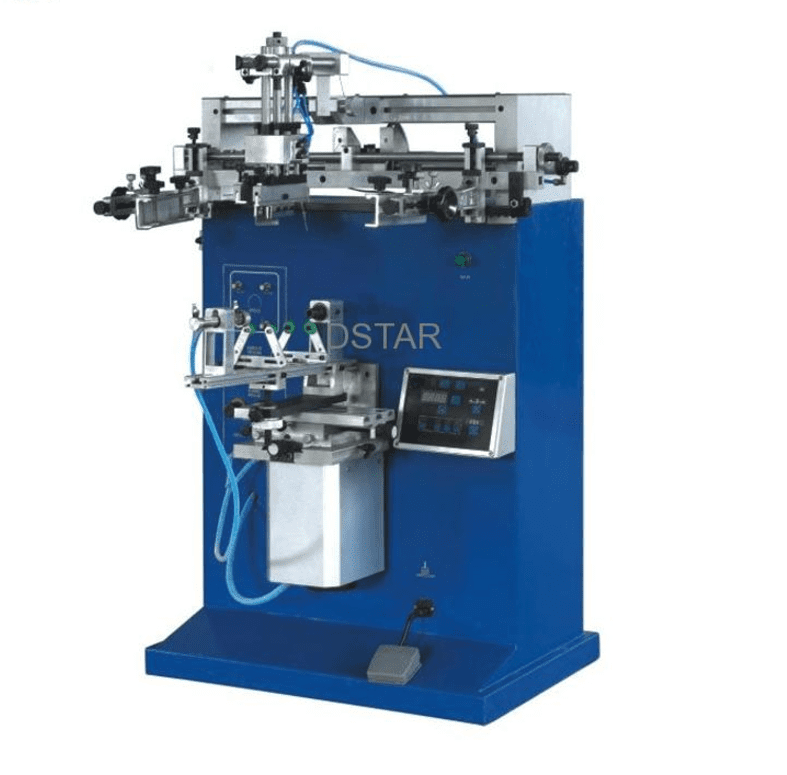

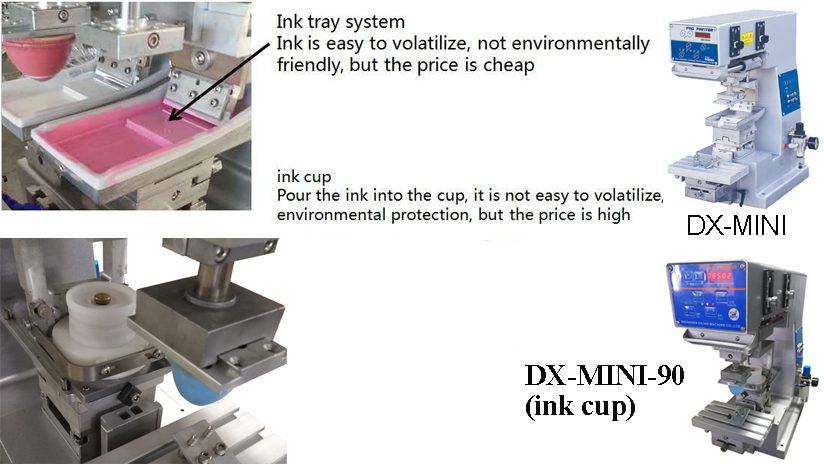

Difference between open ink well and sealed ink cup

- Open ink well systems

Open ink well systems, the older method of pad printing, used an ink trough for the ink supply, which was located behind the printing plate. A flood bar pushed a pool of ink over the plate, and a doctor blade removes the ink from the plate surface, leaving ink on the etched artwork area ready for the pad to pick up.

- Sealed ink cup systems

Sealed ink cup systems employ a sealed container which acts as the ink supply, flood bar and doctor blade all at the same time. A ceramic ring or tungsten ring with a highly polished working edge provides the seal against the printing plate.

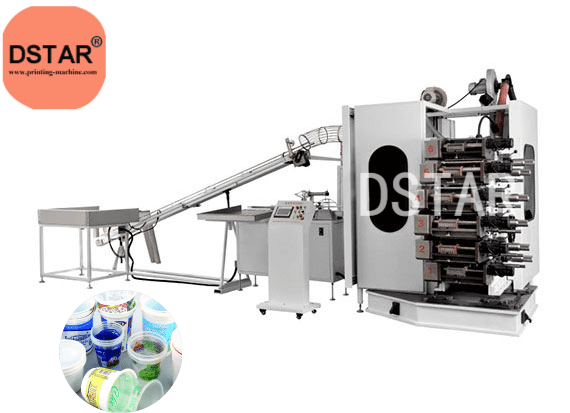

Printing Samples

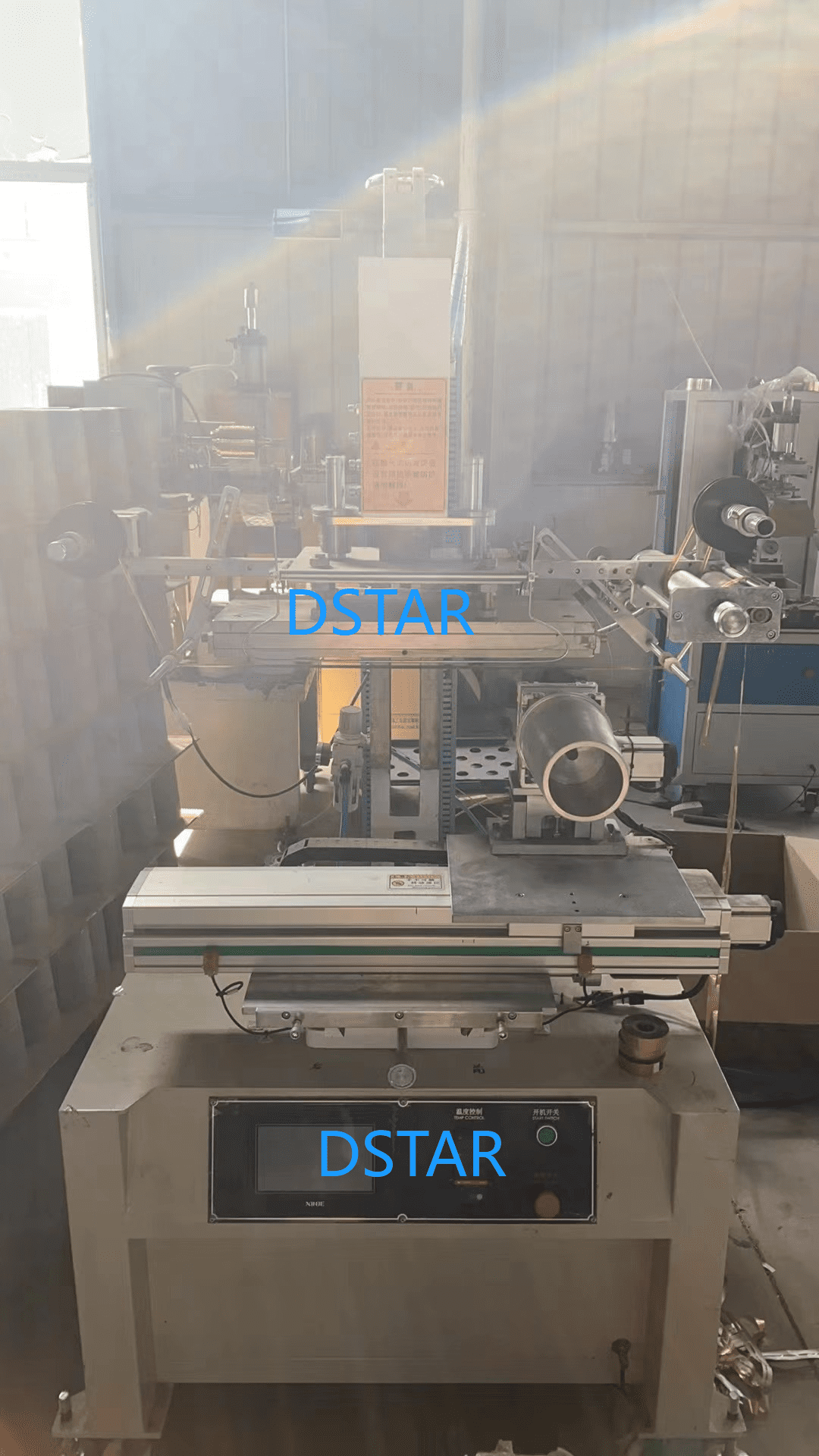

Machine Video

Reference Video 1