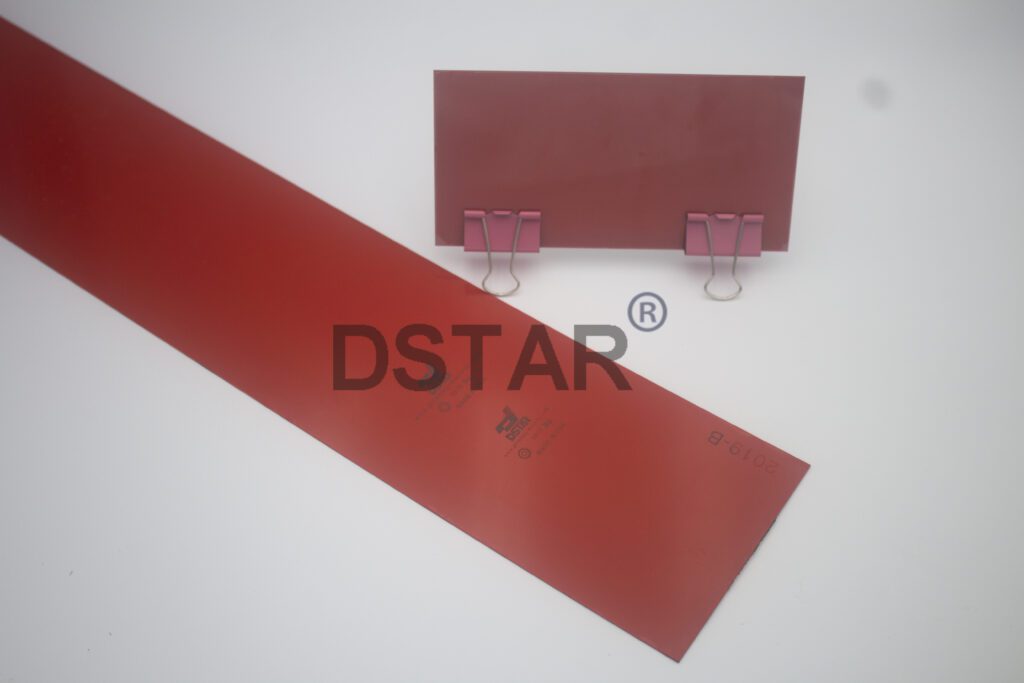

High Quality Water Washing Photopolymer Printing Plate for Pad Printing Machine

Model:DX-WSA52

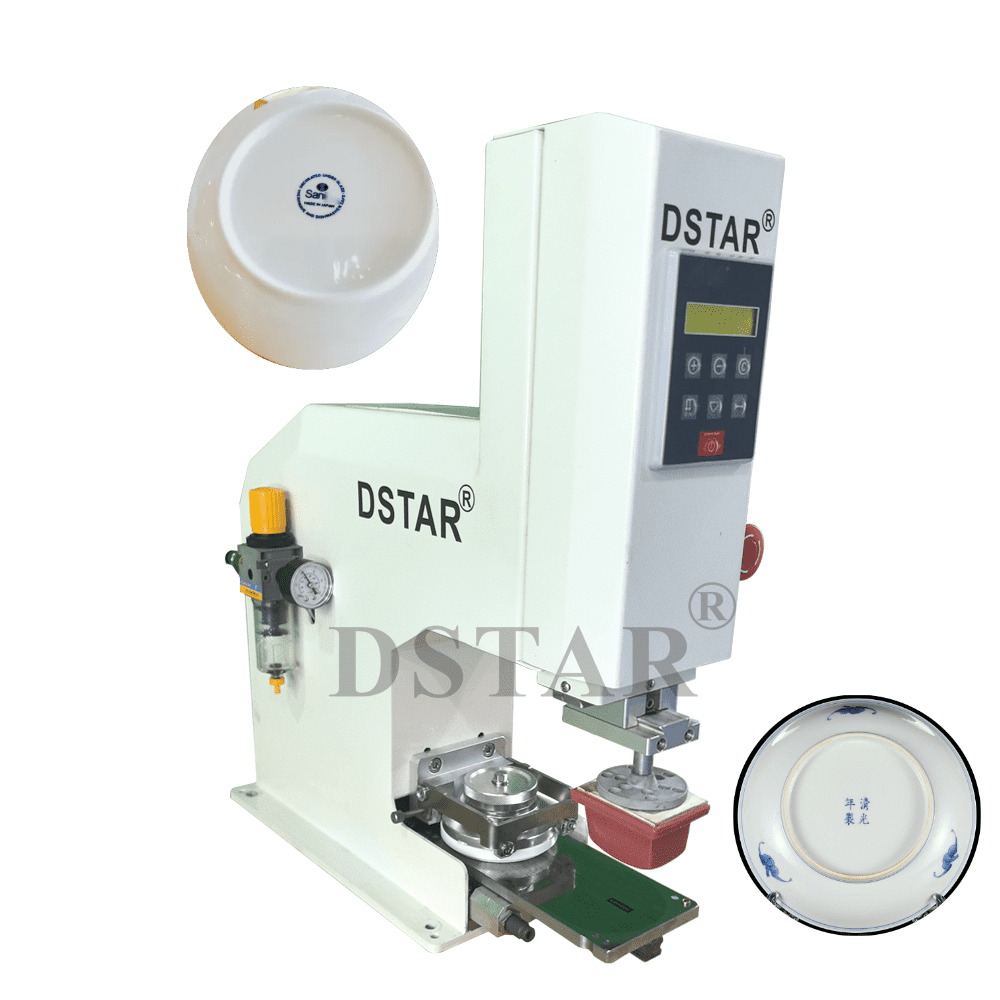

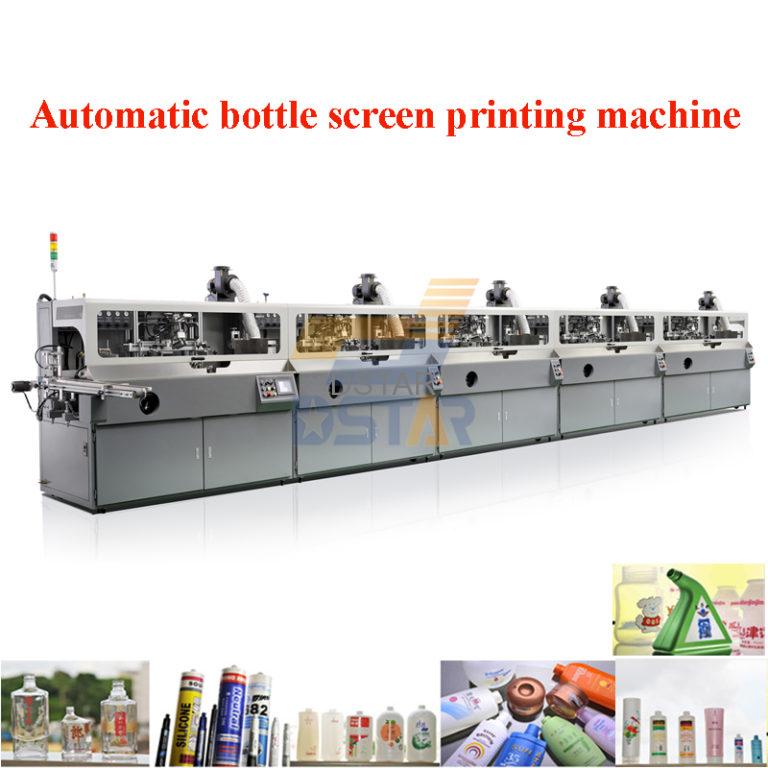

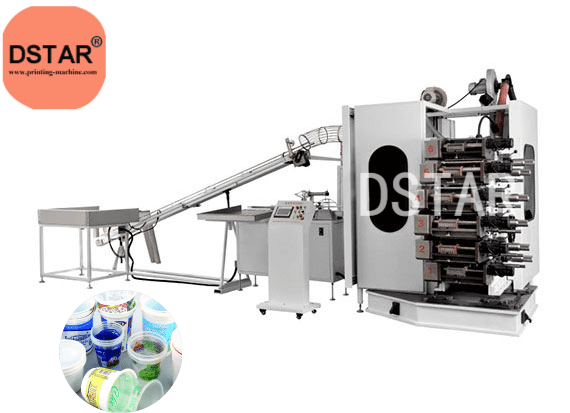

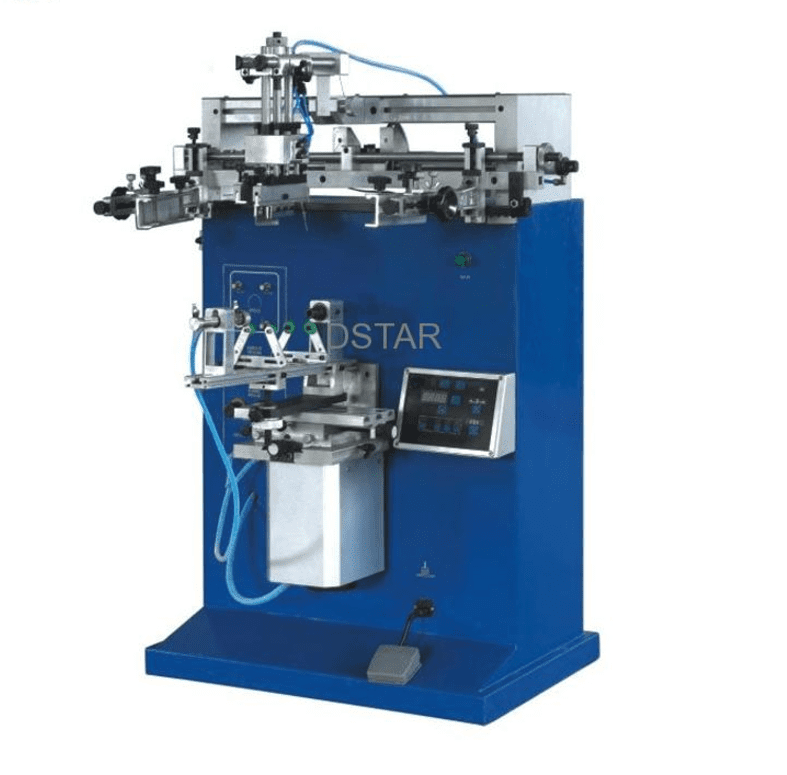

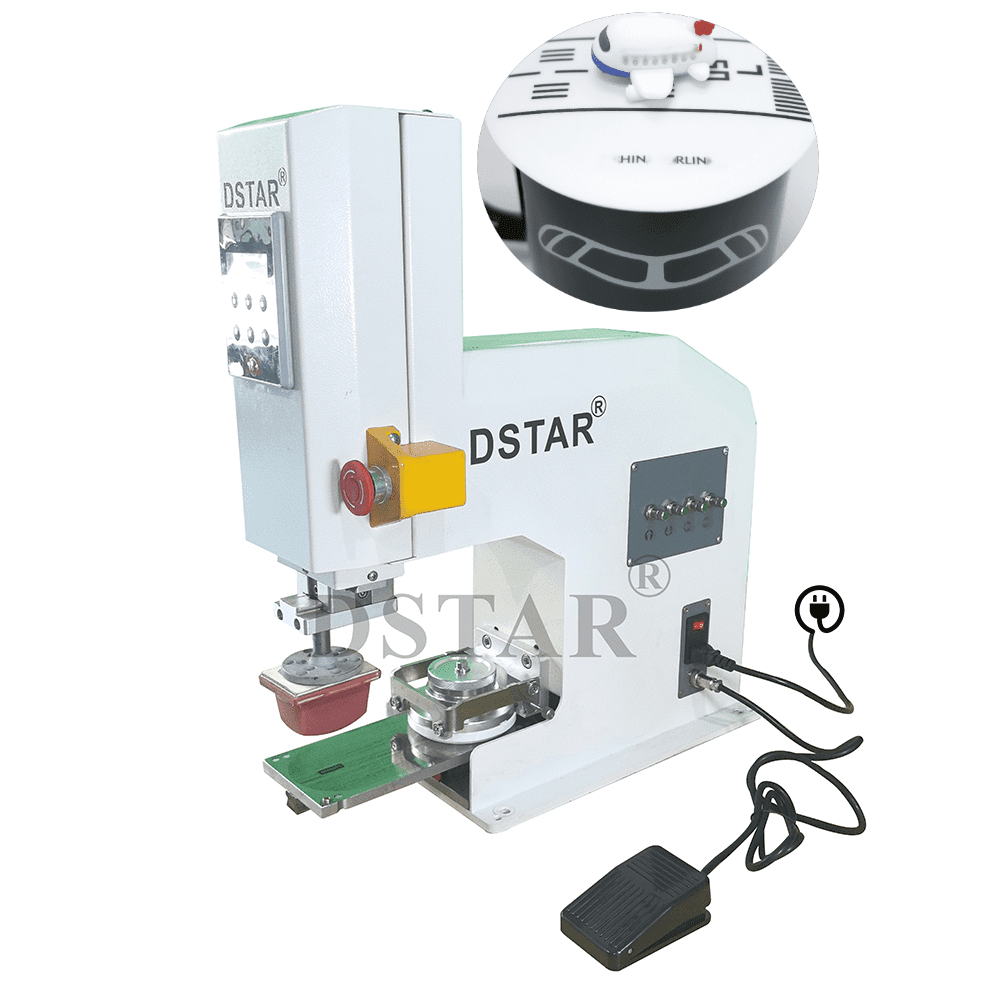

Application:For pad printing machine

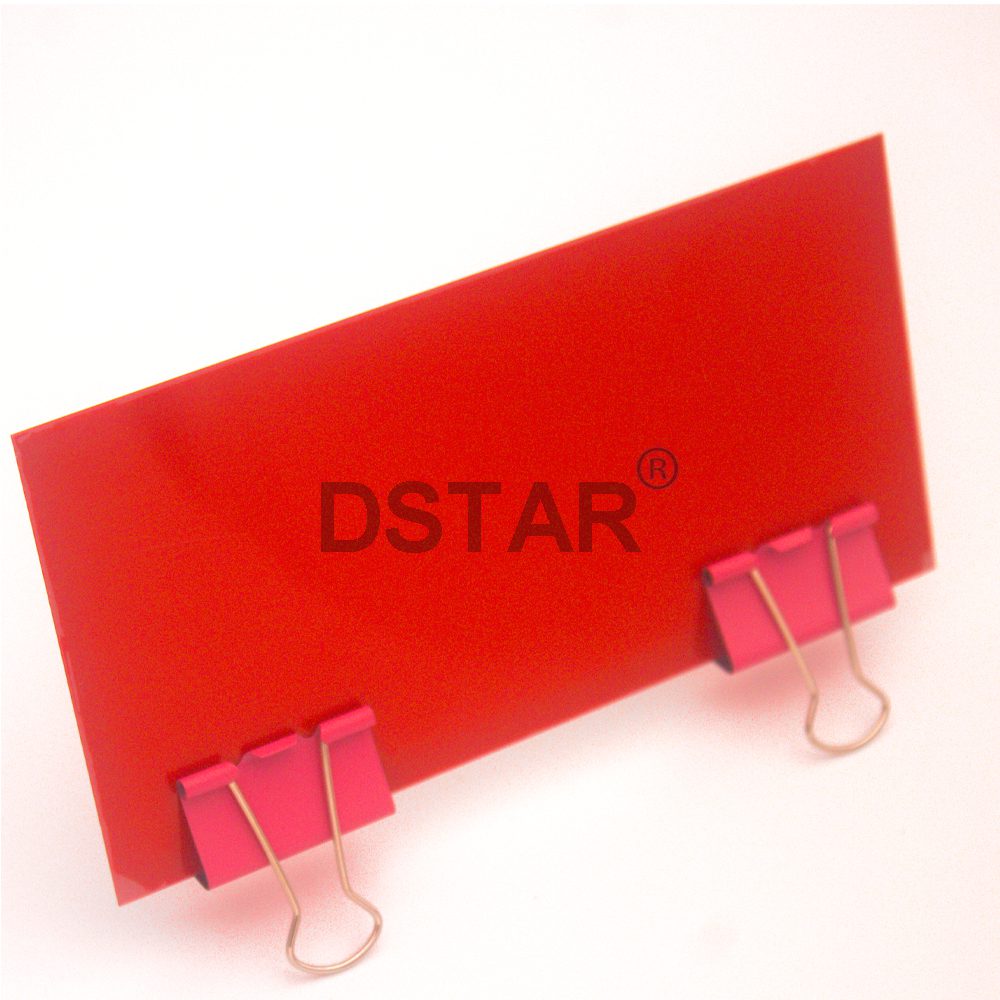

Base material:steel

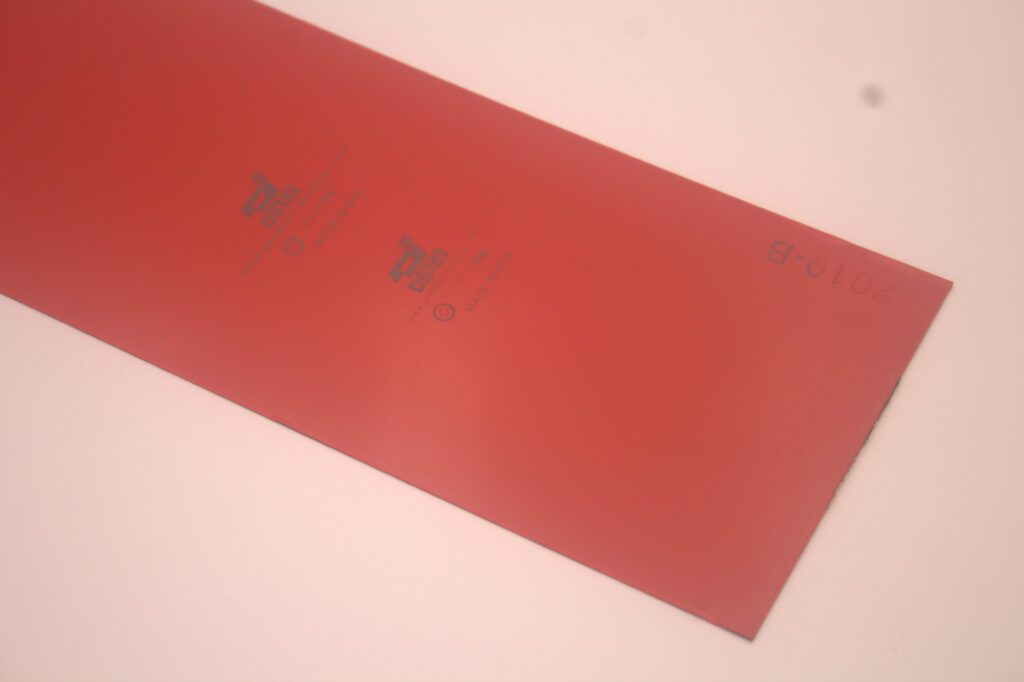

Coating:photopolymer(red color)

Total thickness:0.52mm

Plate hardness:90D

Relief depth:0.2mm

Tonal range:5-95%

Application

- 1、For high quality pad printing, can be also used with closed cup inking systems because of its durability

- 2、For security printing as intaglio master plate and for sheetfed gravure printing

Printing Ink

Suitable for all commonly used pad printing inks, UV and oil based inks.

Washing Photopolymer Printing Plate Features

- 1、For high quality pad printing, can be also used with closed cup inking systems because of its durability

- 2、For security printing as intaglio master plate and for sheetfed gravure printing

- 3、Excellent solid density due to brilliant ink transfer

- 4、Also suitable for pad printing jobs with > 20.000 impressions

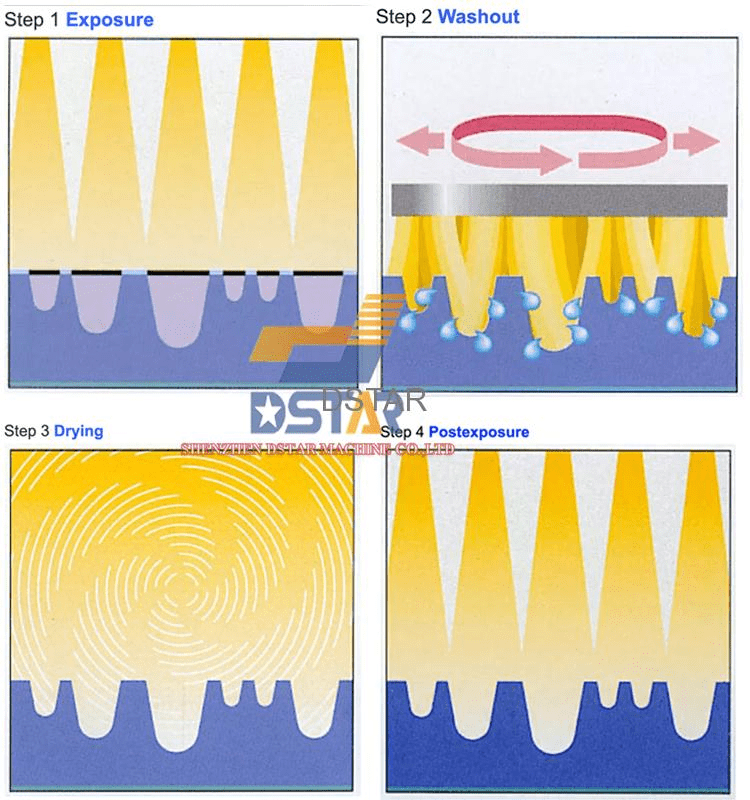

Washing Photopolymer Printing Plate Making Processes

1、Film at screen ruling of:150 l/cm

2、Main exposure:0.5–2.5 Min

3、Washout time:2 Min(water washing)

4、Washout temperature:30°C / 86°F

5、Drying time at:80°C / 176°F 30Min

6、Post exposure:8–10min

Noted:above time may be vary from different exposure equipment

Working Video

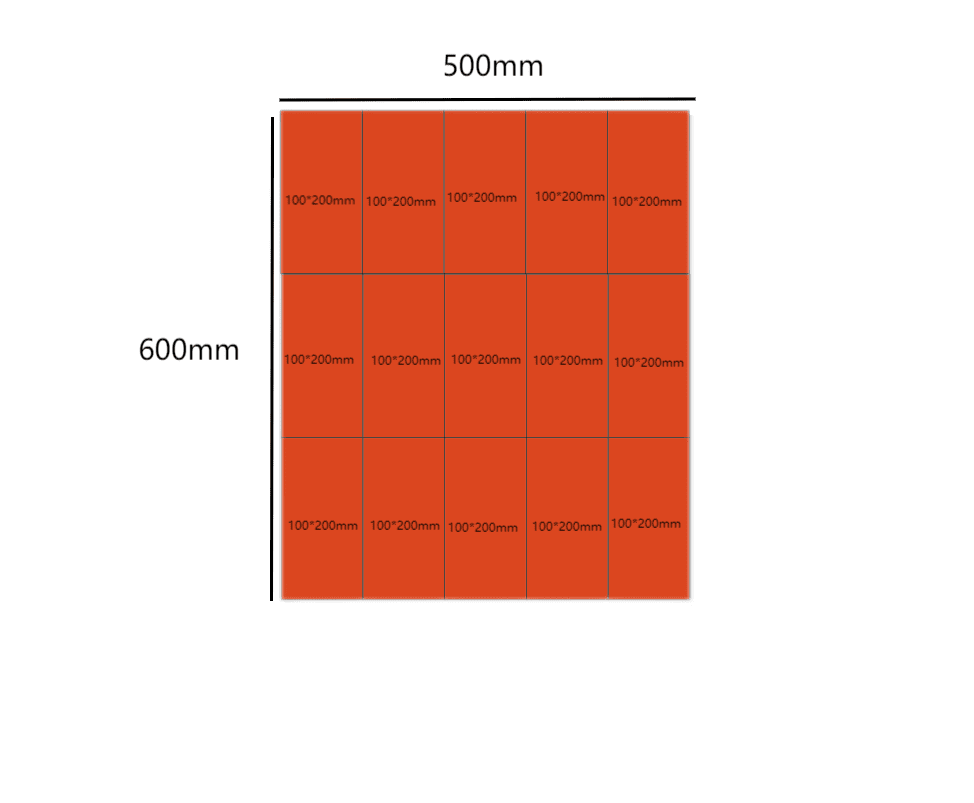

Washing Photopolymer Plate Samples Display

Contact Information